Weld Lines, Knit Lines and Meld Lines

A weld line (weld point,

flow line or a knit line) forms when separate melt fronts travelling

in opposite directions meet. A meld line occurs when two moving

melt fronts converge and flow parallel to each other. Weld and

meld lines are generally caused by holes or inserts in the part,

multiple gates, variable wall thickness or hesitation and race

track effects.

| 1.

The Initial Weld Point |

|

2.

Section through Weld Point |

|

|

|

The

wall thickness of this example is un-even, causing the

weld point to form offset from the centre of the rectangular

hole.

|

|

A

section through the weld point shows the melt fronts meeting

at the centre point of the flow channel where the material

is hottest.

|

| 3.

Temperature Profile Section |

|

4.

Flow Front Temperature |

|

|

|

Typical

fountain flow results in a hot core of polymer flowing

through the centre to the flow front and a frozen layer

at the mould wall. Incomplete joining of the frozen layer

influences weld line visibility. |

|

Un-even

wall thickness causes the flow front temperature to reduce

on the left side of the aperture.

A variation in temperature usually increases the visibility

of the weld line. |

| 5.

Flow Direction @ Weld Point |

|

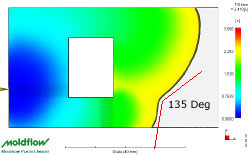

6.

Flow front angle @ 135º |

|

|

|

The

flow direction plot above, shows the change in direction

of the melt fronts as the weld point forms. The weld point

turns into a "meld" as the flow fronts converge

and flow together. |

|

At

the initial point of contact the weld is almost always

visible. Once the angle of the merging flow fronts passes

135º, the weld changes to a "meld" where the

flow fronts move in parallel. see below: |

The Flow Front Meeting Angle The Flow Front Meeting Angle

Traditionally,

a "meeting angle" of 135º is used to differentiate between

weld lines and meld lines, as illustrated in Figure 6.

For most polymers the weld line surface mark tends to

reduce once the meeting angle passes through 120º to 150º.

However, there is always an exception to the rule and

some materials by nature tend to exhibit more visible

weld lines irrespective of the angle. In addition many

fillers and additives also highlight weld & meld lines.

Glass fibres and metallic pigments are good examples. Typical

fountain flow results in a hot core of polymer flowing

through the centre to the flow front and a frozen layer

at the mould wall. Incomplete joining of the frozen layer

influences weld line visibility, therefore mould temperature

and melt temperature are key factors influencing weld

line visual quality and strength.

The exact strength of the weld line depends on the ability

of the flow fronts to weld (or knit) to each other. The

strength of the weld-line area can range from 10 to 90

percent as strong as the pure material. Weld lines are

generally considered to be of lower quality than meld

lines, since less molecular diffusion occurs across a

weld line after it is formed.

Conditions

that are favorable for better weld-line strength include:

High injection pressure and speed; High melt and mold-wall

temperature; Formation of the weld lines closer to the

gate; A temperature difference of less that 10ºC between

the two emerging melt fronts.

If

a weld line forms before the filling phase is complete

and is immediately subject to additional packing pressure,

the weld line will typically be less visible and stronger. The most effective

way to improve the strength of weld and meld lines is

by increasing the local temperature and pressure.

For more information or a quotation please see our contact and RFQ pages.

|